cladding

Back

real cedar cladding

introduction

Back

cladding home

cladding gallery

why real cedar?

western red cedar characteristics

sustainability

biophilia

design & spec

Back

cladding grades

engineered cedar

cladding calculator

building

Back

preparation for installation

pre-building tips

dupont™ tyvek® drainwrap™

installation

general installation

installing profiles

finishing

Back

how to finish

types of finishes

care & maintenance

restoration

cladding profiles and trim

Back

t&g cladding

trim boards

bevel cladding

board and batten cladding

shiplap or channel cladding

shingle panels

western red cedar soffits

decking

Back

real cedar decking

introduction

Back

decking home

decking gallery

why real cedar?

western red cedar characteristics

sustainability

biophilia

engineered cedar

planning

Back

decking calculator

building

Back

fastener recommendations

stair & railing installation

finishing

Back

finishing tips

restoration

care & maintenance

deck projects

Back

roof deck

raised deck

ground level deck

uphill sloping lot deck

outdoor

Back

real cedar outdoor

introduction

Back

outdoor home

outdoor gallery

why real cedar?

western red cedar characteristics

sustainability

biophilia

engineered cedar

design & spec

Back

real cedar free diy project plans

design tips

building

Back

project preparation

outdoor fasteners

fence construction

fence specifications

prebuilt fence panels

finishing

Back

finishing techniques

finishing tips

restoration tips

project care & maintenance

fencing

Back

fencing home

fence construction

fence specifications

prebuilt fence panels

indoor

Back

real cedar indoor

introduction

Back

indoor home

indoor gallery

why real cedar?

western red cedar characteristics

sustainability

biophilia

engineered cedar

building products

Back

building preparation

design tips

finishing

Back

finishing tips

care & maintenance

indoor projects

Back

indoor t&g paneling

cedar saunas

doors & windows

blinds & shutters

timbers

Back

real cedar timbers

introduction

Back

timbers home

timbers gallery

why real cedar?

western red cedar characteristics

sustainability

biophilia

engineered cedar

planning

Back

grades and specifications

building

Back

preparation

installation

maintenance

Back

finishing

restoring western red cedar timbers

care & maintenance

resources

Back

real cedar resources

case studies

gallery

cedar books

|

Installing Shingle Panels

What preparation is needed before installing Western Red Cedar shingle panels?

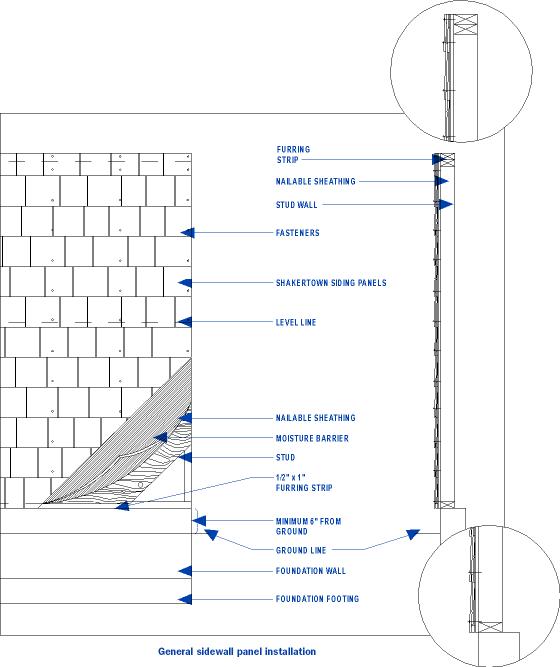

Below are the steps to install Western Red Cedar shingle panels.

Clean surfaces thoroughly prior to installation.

Clean surfaces thoroughly prior to installation.- Prepare surfaces using the methods recommended by the manufacturer for achieving the best result for the substrate under the project conditions.

- Determine prior to framing layout which corner treatment is to be utilized. Panels require a nailable area 5-1/4 inches (133 mm) of outside corners and 3-1/2 inches (89 mm) of inside corners.

- After framing is completed, install building paper horizontally, shingle style, beginning at bottom of wall with 3 inches (76 mm) overlaps.

- Corner boards, trim and molding:

- Shall be extended a minimum 1 inch (25.4 mm) from sheathing to allow for 7/8 inch (22 mm) depth of applied Shakertown Craftsman shingle panels.

How do I install Western Red Cedar shingle panels?

Install in accordance with manufacturer’s instructions.

Install in accordance with manufacturer’s instructions.

- Install shingle panels by attaching to solid nailable sheathing, spaced nailable sheathing or to studs.

- Install working from the lowest level up to the top of the wall area

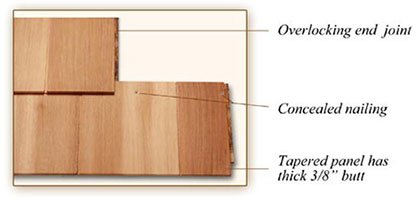

- Furr out the bottom course of cladding with 3/8 inch by 1 inch (9.5 by 25.4 mm) wood strips. Allow for canting of the first course of cladding and install to level line.

- Drive nails flush with cladding surface, penetrating studs at least 1/2 inch (12.7 mm).

- Maintain 1/8 inch (3 mm) spacing at corner boards and trim. Caulk with non-hardening sealant.

- Maintain 1/16 inch (1.6 mm) spacing between ends of panels in order to allow for natural expansion.

- Maintain 1/4 inch (6 mm) space from panel butt line and flashing.

© 2026 All rights reserved

Gatsby Website Development by Jambaree